LIGHTBELT LED shaft lighting for lifts –

brilliantly simple, brilliantly safe!

Since 01 September 2017, the new European elevator standard EN81-20/50 has been mandatory. Among other things, this standard provides improved lighting for lift shafts. With uniform and bright LED light, LIGHTBELT fulfils these new requirements perfectly.

The complete LIGHTBELT system

It consists of

Good ideas always come out on top

– like LIGHTBELT, the brilliant LED system for lift shaft lighting. The inventor and designer of technical lift components Jürgen Andretzky noticed that the advantages of modern LED lighting in lifts was increasingly used in the area of the lift car. However, safety-relevant lighting in the lift shaft is frequently eliminated in the modernisation cycles. He followed his observation with actions and joined forces with LIGHTBELT to develop a light strip that combines the greatest ease of assembly with the highest flexibility and best possible illumination. LIGHTBELT thus makes a significant contribution to the safety of assembly operators working in the lift shaft.

Technical data

| Lichtstrom Luminous flux |

1.000 lm/m 1,000 lm/m |

| max. Länge max. length |

100 m |

| Kürzbarkeit Cutability |

0,5 m 0.5 m |

| Querschnittsfläche Schacht 20 Lux (berechnet) Cross-section area well 20 Lux (calculated) |

max. 18 m² |

| Querschnittsfläche Schacht 50 Lux (berechnet) Cross-section area well 50 Lux (calculated) |

max. 7 m² |

| Spannung Voltage |

220-240V AC / 50-60Hz |

| Leistungsaufnahme Input power |

9 W/m |

| Anzahl LED/m Amount LED/m |

84 LED/m |

| IP Schutzart IP protection class |

IP 54, IP67 (optional) |

| Farbtemperatur Color temperature |

6.000 K 6,000 K |

| Abstrahlwinkel Beam angle |

120° |

| Betriebstemperatur Schlauch Operating temperature |

+20°C bis +40°C +20°C to +40°C |

| Umgebungstemperatur Schacht Ambient temperature well |

-20°C bis +45°C -20°C to +45°C |

| Lebensdauer bei normal Betrieb Working lifetime |

20.000 Stunden 20,000 hours |

| Maße Lichtschlauch Dimension light-strip |

16 x 11 mm |

| Gewicht ohne Zuleitung Weight without supply line |

0,18 kg/m 0.18 kg/m |

| Zuleitung Supply line |

2 m Euro-Plug / 5 m, 10 m offenes Ende / WAGO 2 m europlug / 5 m, 10 m open ends / wago |

| Befestigungsart Fixing type |

2 Schrauben (im Lieferumfang erhalten) 2 screws (received in the scope of delivery) |

| Material Lichtschlauch Material strip |

PVC, selbstverlöschend PVC, self-extinguishing |

| Schutzklasse Protection class |

II |

| Zertifikate Certificates |

CE, ROHS, REACH, EMC |

| Normen Standards |

DIN EN 81-20, DIN EN 81-72, DIN EN IEC 60598-1 DIN EN 60598-2-21, DIN EN 62471 (RG0) |

| Zubehör Accessory |

Zugschalter, E-Box, Dimmer, Verlängerung 10 m Pull switch, E-Box, dimmer, connection coupling 10 m |

| Gleichrichter Rectifier |

auf Platine (im Schlauch) on board (in the strip) |

| Abkühl-Phase Cool-down period |

keine cool down phase without cool-down period |

LIGHTBELT assembly

As a complete system, LIGHTBELT is brilliantly simple and quick to install. Existing lift shafts with fluorescent tubes can also be retrofitted without problems. Only two mounting points are required for hanging, between which the light strip is clamped. Everything you need for the installation is included in the scope of supply. And since lift shafts can have very different lengths, the light tube can be adapted to all shaft lengths individually and be shortened by us every 50 cm. LIGHTBELT can thus be integrated into any existing passenger or freight lift to ensure radiant brightness and higher safety in the lift shaft.

Mounting at the top of the lift shaft:

At the upper mounting point, one screw is enough to hold the light strip. To do this, drill a hole in the desired place and screw the supplied special screw with thread and without dowel directly into the wall. For this purpose, an impact wrench with insert TORX Bit T30 is required.

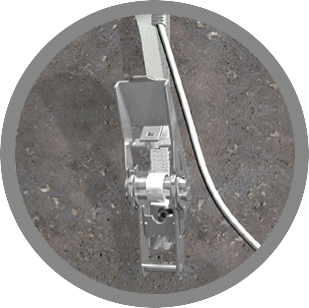

Mounting at the bottom of lift shaft:

Transfer the drilling point of the ratchet to the wall using a marker pen. Drill another hole at the marked point. Then the ratchet is fixed to the shaft wall of the lift using the supplied special screw T30 without dowel. Then tension the light strip with the ratchet until it is tight. Now just insert the plug into the socket, and the lift shaft is immediately flooded with a bright, pleasant working light to provide comfort and safety for the assembly operators.

The new EU standards

After a two-year transition period, the new lift standards DIN EN 81-20/50 become mandatory for all new passenger lifts and freight lifts on 1 September 2017. These standards specify the safety requirements applicable to lifts. The new, more stringent specifications for passenger and freight lifts also apply to lighting: A general minimum luminous intensity of 20 lux is prescribed, or 50 lux 1 m above the car roof in each car position and in the shaft pit. The purpose of this is to effectively reduce the risk of accidents during maintenance and repair work.

For passenger lifts, freight lifts or goods lifts alike: With uniform and bright LED light with a luminous intensity of 1,000 lumen/m, LIGHTBELT fulfils the new requirements perfectly.

Effective 1.September 2017

For passenger and goods lifts

At least 20 lux in the shaft